550 Mm Guide Gasoline Saw 2 Punch 20 "Hand-Held Noise-Damping 6kg

Fuel-Efficient Chainsaw

Feature

High strength aluminum-magnesium alloy cylinder

This chainsaw uses a high-strength aluminum-magnesium alloy as the

cylinder material, which is lighter than the ordinary steel

cylinder, and has excellent corrosion resistance and impact

resistance. This high-strength cylinder design not only ensures the

robustness of the body, but also helps to reduce the weight of the

machine and improve the ease of operation.

Perfect cooling system

In order to ensure the stability and reliability of the chainsaw

when used for a long time, the model uses a complete cooling

system. By optimizing the design of the heat sink and the layout of

the air duct, the heat can be effectively discharged quickly,

ensuring that the engine is always kept within the optimal

operating temperature range, avoiding the problem of performance

degradation or parts damage caused by overheating.

Suspension dual-arm damping system

The chainsaw uses four independent air column shock absorber

springs to form a set of suspension dual-arm shock absorber system.

This design can effectively absorb the vibration generated during

operation, greatly reduce the recoil and vibration during use, make

the cutting more smooth and stable, and greatly reduce the

operator's fatigue.

Noise reduction technology

In order to ensure a more comfortable and quiet working

environment, the chainsaw uses advanced noise reduction technology.

By optimizing the engine exhaust system and fuselage structure

design, the working noise is effectively reduced, making the

operation more quiet and easy. This is especially important for

scenarios that are used for long periods of time.

Secondary quenching chain

The chain of the chainsaw is the key component that determines the

cutting efficiency. This chainsaw uses a high hardness chain after

secondary quenching treatment, not only can maintain a longer sharp

edge, but also the chip removal effect is better, and the cutting

process is not easy to get stuck.

Tuning technique

In addition to hardware improvements, the chainsaw has also put a

lot of effort into tuning technology. Precision carburetor tuning,

for example, ensures that the engine maintains optimum fuel

efficiency and power output in all operating conditions. At the

same time, it is deeply optimized for various working environments.

Fuel-efficient diaphragm carburetor

To further improve fuel economy, the chainsaw uses a diaphragm

carburetor design. The carburetor's more sophisticated construction

allows for more precise oil/gas mix adjustment, which significantly

improves fuel efficiency and reduces fuel consumption.

Add large double hole exhaust pipe

The optimization of the exhaust system is also a highlight of the

chainsaw. The use of large double-hole exhaust pipe design, not

only can improve the flow of exhaust gas, reduce exhaust

resistance, but also can better control exhaust emissions, to

achieve a more environmentally friendly combustion effect.

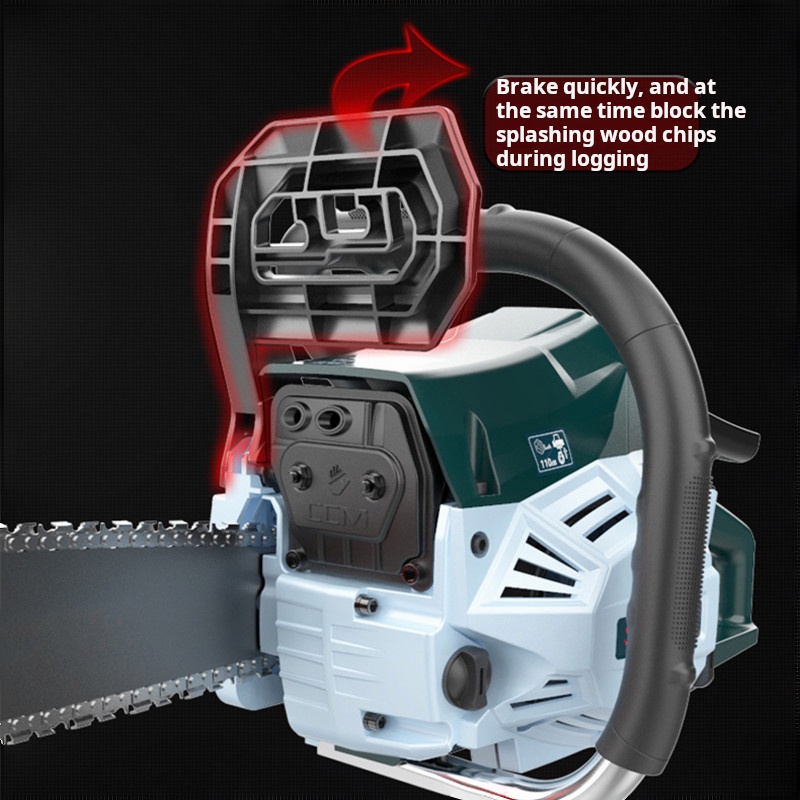

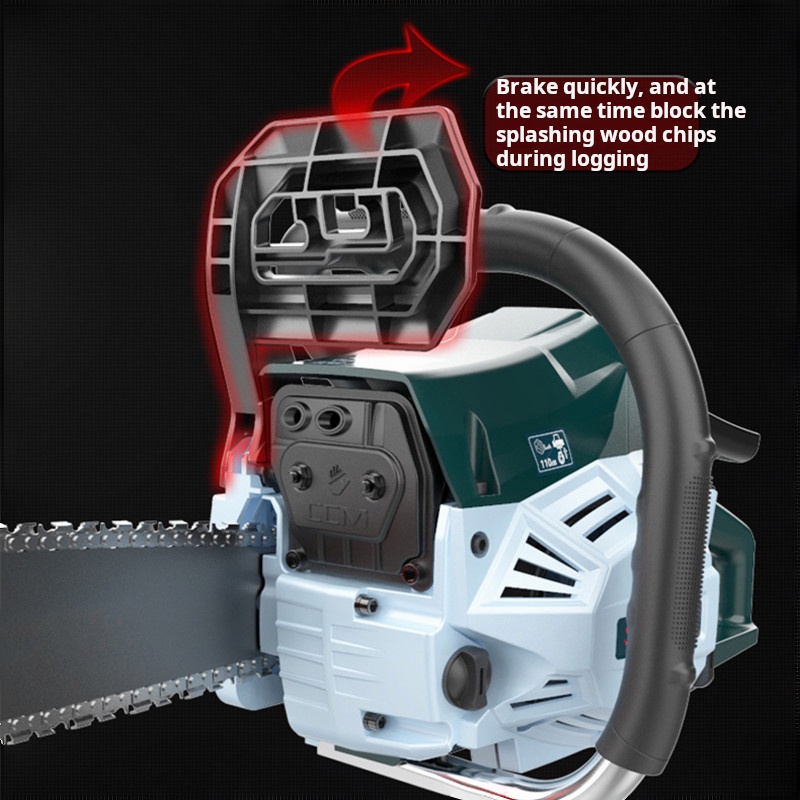

Quick braking

To improve operating safety, the chainsaw is also equipped with a

fast braking system. In the logging process, if there is an

unexpected situation, the operator only needs to gently pull the

brake handle, which can quickly stop the chain operation and

effectively prevent the splashing of wood chips from causing injury

to the operator. At the same time, the brake handle adopts the

design of strengthening and thickening, which is more firm and

durable.

Specifications

| Product Name | High-Power Chainsaw |

Rated Power | 2.6 KW |

| Rotation Speed | 12000r/min |

| Tank Capacity | 260ml |

Fuel Tank Capacity | 550ml |

Maximum Cutting Diameter | 20 inches (70cm) |

Engine Specification | 58.0cc |

| Color | Dark green white patchwork |

| Weight | 6.3kg |

Dimension | 500*250*340mm |

| Type | Hand-Held Chain Saw |

| Peculiarity | High temperature resistance, shock absorption, safety switch |

| Application | Logging, Engineering |

Customization Range | Color customization, package configuration customization |

Product Details

Company Profile

Founded in 2005, Sichuan Baiyibang Trading Co., Ltd. is a leading

enterprise specializing in the import and export trade of hardware

tools, power tools and custom chemical tools. Headquartered in

Chengdu, the company has branches in Europe, the United States and

the Middle East, forming a marketing network covering major markets

around the world.

Product advantage

The company has always adhered to the concept of "quality first",

and is committed to providing customers with excellent performance

and reliable quality products. Our products are from well-known

manufacturers in China. These partners not only have a pivotal

position in their respective fields, but also have advanced

technology and exquisite workmanship, which are widely favored by

global customers.

Our hardware tools, power tools and custom chemical tools are

produced in strict accordance with international standards,

excellent materials and long service life. At the same time, we

also have a professional product research and development team, can

provide customers with personalized customized services to meet the

needs of different industries and different application scenarios.

Service advantage

The company is committed to providing customers with one-stop

solutions from procurement to logistics. We have independent

logistics company, can provide warehousing, transportation, customs

clearance and other logistics services. The huge logistics network

and rich experience ensure the efficient, punctual and safe

delivery of goods.

At the same time, we have also established a perfect after-sales

service system. The professional technical team is on standby to

provide customers with a full range of services such as use

guidance, maintenance and so on to ensure that the product

experience is high-quality and reliable.

Customer reputation

With high quality products and considerate service, the company has

won a high degree of recognition from customers. Our customers are

all over the world, including well-known companies in many fields

such as automobile manufacturing and construction machinery. These

customers have fully affirmed our professional strength and service

level, and have established a long-term and stable cooperative

relationship with us.

Looking forward to the future, the company will continue to adhere

to the "integrity management, the pursuit of excellence"

development concept, to provide global customers with better

quality products and more intimate service.

About Factory

The factory focuses on the development and manufacturing of

hardware tools, with 16 years of long industry history. After years

of unremitting efforts, the company has developed into a leader in

the domestic industry, in terms of product quality, production

technology and brand influence are in the industry leading

position.

We have an experienced R&D team dedicated to developing

innovative products that meet the needs of the market. With

profound technology accumulation and keen insight into industry

dynamics, we continue to pay attention to market hot spots, keep up

with the forefront of the industry, and constantly introduce new

products with excellent performance and exquisite craftsmanship.

In the manufacturing process, it is equipped with advanced

production equipment to ensure that the product manufacturing

process is excellent. At the same time, the company has a sound

quality management system, raw material procurement, production and

processing, finished product testing and other links are strictly

checked to ensure stable and reliable product quality.

In terms of brand building, we actively participate in various

exhibitions and exchange activities in the industry, and

continuously enhance the brand influence through high-quality

products and professional services.

With continuous improvement of product quality and service system,

we have won high recognition from a wide range of customers. The

company's products are exported to Europe, North America, the

Middle East and other major global markets, customers throughout

the automobile manufacturing, machinery and equipment, home

improvement and other industries

Packing/Delivery

FAQ

Q1: What certifications do you have for your hardware tools?

A1: Our hardware products usually meet international standards and

certification requirements, such as CE certification, RoHS

certification, ISO certification and so on. The specific

certification status can be confirmed according to the product.

Q2: Do you offer customized hardware tools?

A2: Yes, we can provide customized hardware tools according to

customer's needs, including customized packaging, printing

customer's brand or logo, specific specifications and sizes of

tools, etc.

Q3: What are the prices of your products?

A3: The price of our products is very competitive. The specific

price depends on the type, specifications and order quantity. We

will provide specific quotes and offers according to customer

needs.

Q4: Do you provide samples?

A4: Yes, we can provide samples for customers to evaluate and test.

Sample costs and shipping will be determined on a case-by-case

basis, but sample costs can be deductible or refunded in subsequent

official orders.

Q5: Do you accept small orders?

A5: Yes, we welcome small orders. We understand that customers may

need to conduct trial marketing or meet specific market needs, so

we will do our best to meet the needs of our customers.

Q6: What is your delivery time?

A6: Delivery time depends on factors such as product type, order

quantity and production capacity. We will confirm the delivery time

according to the order and try to provide fast and on-time delivery

service.

Q7: What kind of payment terms do you offer?

A7: We usually accept payment by T/T, Western Union, L/C, etc. The

specific payment method can be determined by contract negotiation

and mutual agreement.

Q8: Do you provide after-sales service?

A8: Yes, we provide comprehensive after-sales service. If we

encounter any problems or quality problems during use, we will

actively assist in solving them and provide necessary technical

support and after-sales guarantee.